how to clean the nozzle

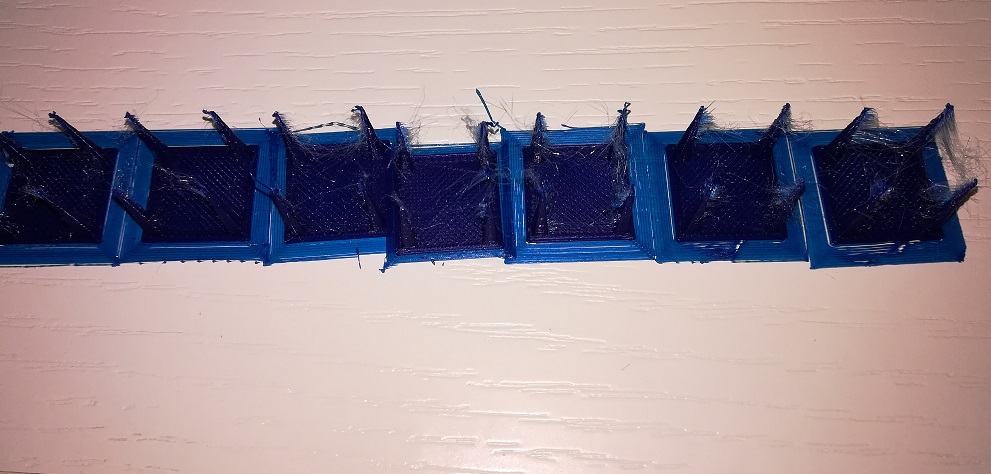

The world of 3d printing, especially for those who deal with it at a hobby level, is unfortunately not free from problems. An unexpected event that can happen is that related to the obstruction of the nozzle of our hotend on the part of the filament. Fortunately, it does not happen often and in any case there are many ways to clean it, for example it is often sufficient to extrude a material with a higher operating temperature than the one causing the cork, or if the block was due to the abs, a bath of a few hours in acetone often solves the problem. In my specific case, the block was due to some plaque that I had neglected, causing it not only to deteriorate but also to dust. This caused, after a few minutes of printing, an obstruction of the nozzle which was not easy to remove with the most common methods. So I came up with a “soooo homemade” way to clean the nozzle.

Continue reading clean the nozzle