There are many causes and many possible solutions to the very common problem of lack of adhesion.

The effects can be different, for example the difficulty can occur as soon as the print begins, the filament does not adhere to the plate and it starts to follow the hotend’s movements, in this particular case we can try to adjust the distance between the plate and the nozzle, making sure that it rests the same for all the four corners of the glass.

We can easily adjust the distance by using a sheet of paper, it has to barely pass between noozle and glass.

If instead the problem occurs after the beginnign of the print, or even in an advanced state, maybe the hair spray is not fixative enough, or maybe the first layer’s speed is too high.

We can also try by adding 5/6 mm of BRIM especially if the piece that we’re going to print has a large surface that is in contact with the plate.

BRIM can be helpful because it creates a sort of frame around the object that we want to print, so it increases the size just of the first layer, increasing the adherent surface.

The frame will be easily removed after the end of the print with a simple cutter.

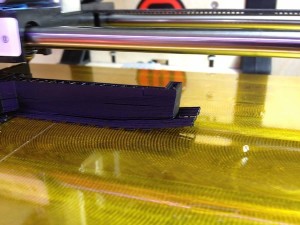

We’ve read that some people use a particular adhesive tape which is put on the bed, many use the coachbuilder’s tape, many others use a specific one called Kapton or BlueTape. We’ve never tried to use it so we have no personal experience, but we have read positive comments for both.

if you want to be updated on the next article, fill in the following fields to subscribe to the newsletter.

Facebook Notice for EU!

You need to login to view and post FB Comments!