not manifold, we understand what it means and how to remedy it

When we design and then draw a three-dimensional model to then be able to make it printed in 3d, we must take into account many factors, for example that the slicer will have to “slice” it to obtain all the coordinates to be used to carry out the physical construction by layering our three-dimensional object.

Once the drawing is finished and our file is fed to the slicer, we can find ourselves in front of a warning message that tells us “attention, the object is not manifold”.

What does it mean? In the case of 3d printing, a non-manifold object is an “non-closed” object, that is, it has imperfections that do not allow continuity during the printing phase. For example, it may be a wall that we apparently designed perpendicular to another but which actually has a minimal, practically invisible, deviation from the contact one.

let’s try to understand better ….

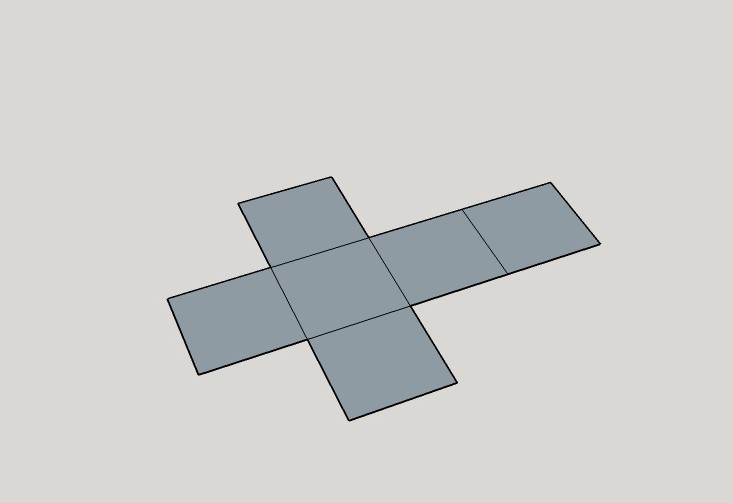

Surely as children we will have created our paper box by drawing the 6 faces that make up the cube on a sheet

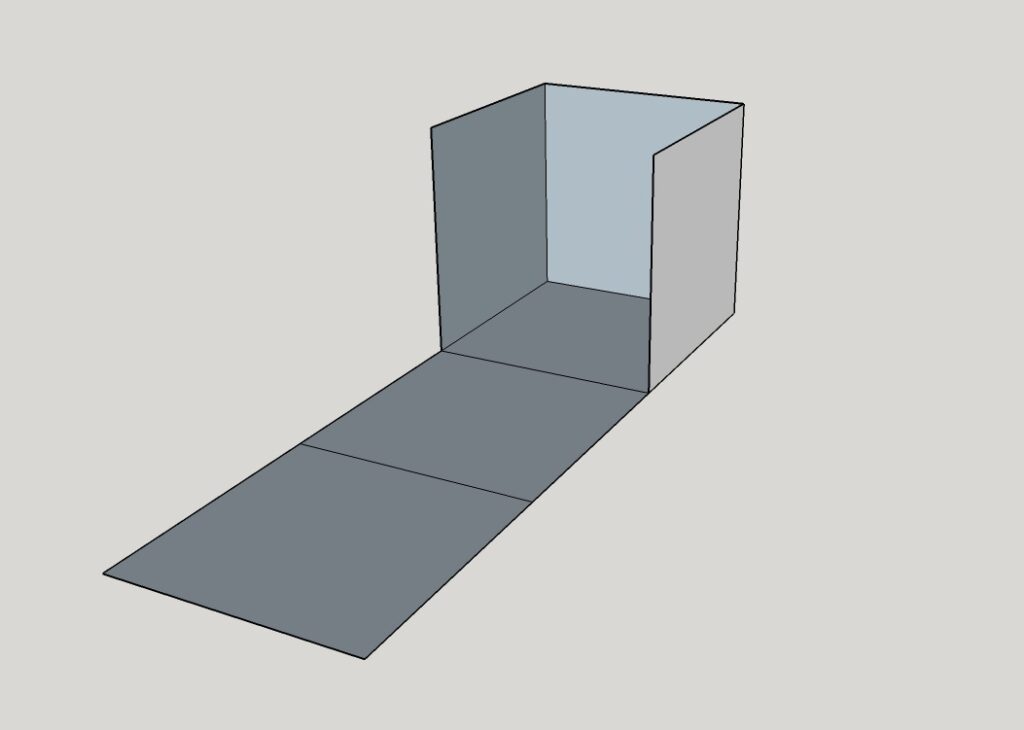

Then folding them according to logic to form our cube

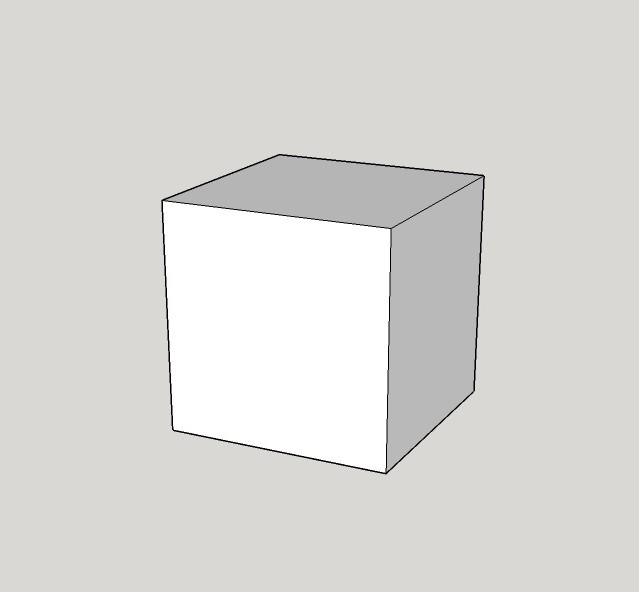

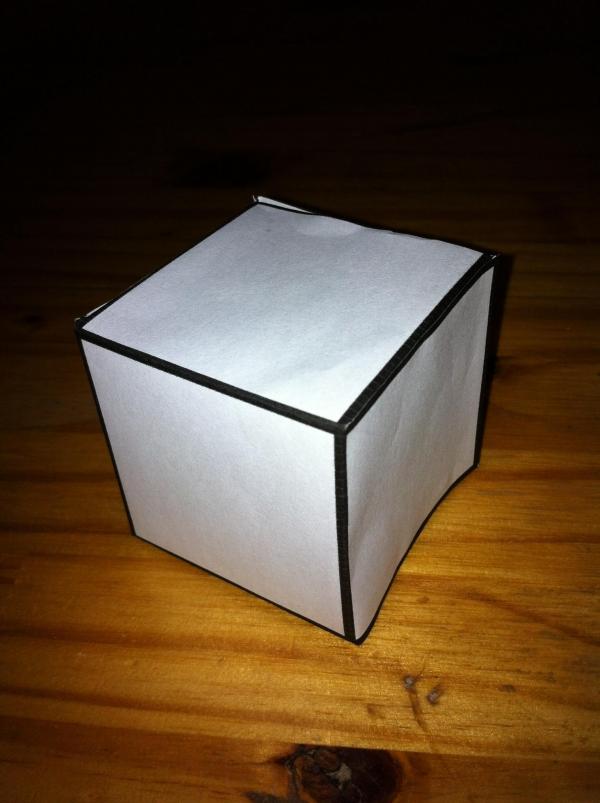

Once all the faces have been folded, we have certainly tried to give “solidity to the cube, perhaps with glue or tape.

The result was certainly good for us even if in reality there were imperfections, such as empty spaces between the junction lines of the cube walls.

In the case of 3d printing, these empty spaces do not allow the slicer to create the continuity of the points needed to build the piece, and the object will be non-manifold.

What can we do? Either we pay much more attention during the design phase or we can rely on software that finds and understands the problems of the design and “repairs” the file, closing all those missing spaces to make the slicer work well.

Many 3D design software incorporate tools that perform the analysis of the object (mesh) and repair the piece by themselves, but most of these are plugins or additional paid features. It is also true that these tools, once you have learned how to use them, allow you to make precise repairs with parameters that can be modified for our needs.

Alternatively, there are several online services that offer for free or upon registration the analysis and subsequent repair of the file, in some cases there is a limit on the maximum size of the file to be uploaded but it is generally very high.

One of the most popular online services is the one made available by netfabb, just have an account, upload the file, wait for the model to be repaired and download the STL ready for printing, safe, practical, fast and reliable.

Another service that I was able to try is the one offered by aspose, in addition to repairing the file it also offers us a choice between some file formats for download, it also offers a preview of the final result.

Simple, fast, very efficient is the free service offered by FormWare, no registration is required, just upload the file and he does the rest. Until now it is the one that has never disappointed me in terms of quality of the produced file and this service also offers a comparison of the three-dimensional model before and after the modification. It accepts and produces only stl files.

Upon free registration makeprintable provides an online service among the fastest and most effective that I have had the opportunity to try and once made manifold our object offers the possibility to choose to downloor subscribe to the newsletter.ad the file in various formats such as obj, stl, 3mf and others.

Also Microsoft provides a free, fast and effective service, unfortunately, certainly to encourage the use of its software for 3d printing, it allows the manifold file to be downloaded only in 3mf format.

Here ends this brief collection of online resources to make manifold our three-dimensional models that have given mesh problems during the slicing phase.

if you want to know more, if you need help write to info@3deasy.it

if you want to be updated on the next article, fill in the following fields to subscribe to the newsletter.