retraction, what it is, what it is for and how it is regulated.

The retraction is the consequence of a series of precautions that we can adopt to avoid the phenomenon of “stringing” or … a spider web that forms especially in the case of small prints with cantilevered parts close together. This problem ruins the aesthetic aspect of our prints and produces an impressive amount of very small filaments that can also naturally detach from the piece and then fall into our 3d printer risking to end up on mechanical and / or electronic parts creating the related problems of the case.

Why are these little “hairs” created?

Suppose we have to print on a base two small solid cylinders at a short distance from each other. Our hotend, after having printed the base, will begin to create the two cylinders layer by layer, thus passing from a phase of extrusion of material to one of non-extrusion and again to one of extrusion. All in a relatively short time.

Imagining the work that the extruder has to do, we can try to think that it has to push the filament in the right amount to create the layer, stop, wait to be moved into position to do the same job for the other cylinder. two phases of layer creation, even simply by gravity a bit of melted filament tends to come out of the nozzle and therefore to create this annoying “fluff”.

Let’s see what retraction is

The retraction consists in retracting a small portion of the filament to compensate for the escape of the melted filament itself. There are few but essential parameters to adjust to ensure that the retraction has the desired effect and they are not difficult to regulate, but we must also think about the unwanted effects that are likely to create by enabling retraction in our slicer.

The retraction consists in retracting a small portion of the filament to compensate for the escape of the melted filament itself. There are few but essential parameters to adjust to ensure that the retraction has the desired effect and they are not difficult to regulate, but we must also think about the unwanted effects that are likely to create by enabling retraction in our slicer. Imagine that for some types of prints if the retraction operations are many and all approached, the work of the extruder motor will make the filament go back and forth many times and therefore the knurled pinion will risk abrading the filament by working very often on the same point and the wider the movement of the wire, the knurling of the pinion will “scrape” the wire on the same section several times. Furthermore, moving the filament too high may cause it to end up in an area of the hotend where the temperature is lower.

This thermal variation can increase the volume of the wire causing it to lock inside the hotend. Another important factor is the speed with which the wire is moved and it depends on our extruder. Obviously, direct or bowden extruders have different behaviors and therefore different adjustments.

Also the melting temperature has its role in the retraction and is easily understood, a high temperature facilitates the formation of the hairs and a low one risks producing a bad extrusion if not the blocking of the wire directly in the nozzle.

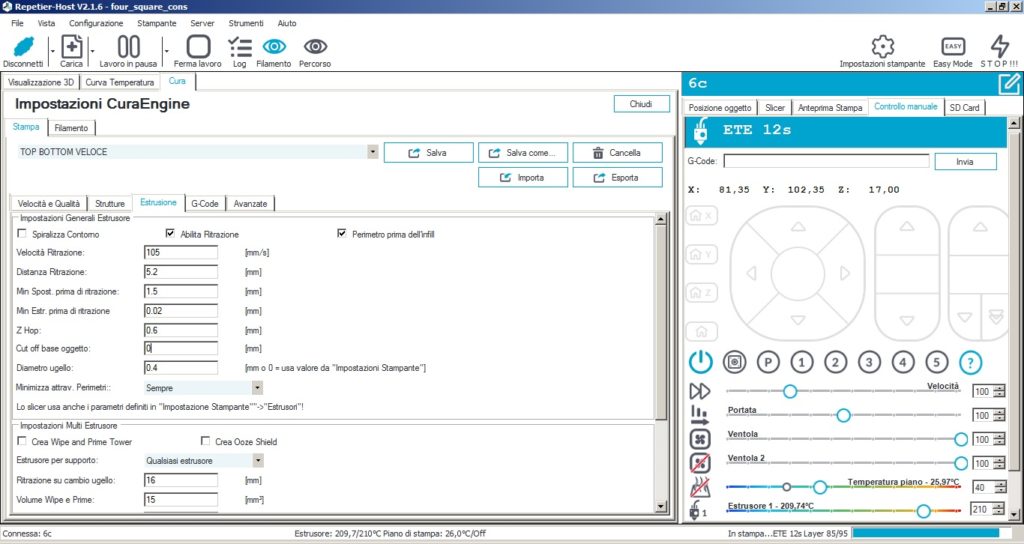

What happens by changing these parameters on the repetier host? Let’s find out using a file found here on thingiverse created specifically for the purpose.

let’s start the test

In my case I use an indirect extruder (bowden) with a tube length of about 70 centimeters and I had parameters set on the cura engine already defined for the type of prints I usually make, that is a speed of 105 mm / s, a distance of retraction of 5.2 mm and 210 ° degrees as the melting temperature.

I used a PLA to tell the truth a little old and measuring the diameter with a caliber, this went from 1.75mm to 1.87mm therefore a filament not exactly optimal for a good print.

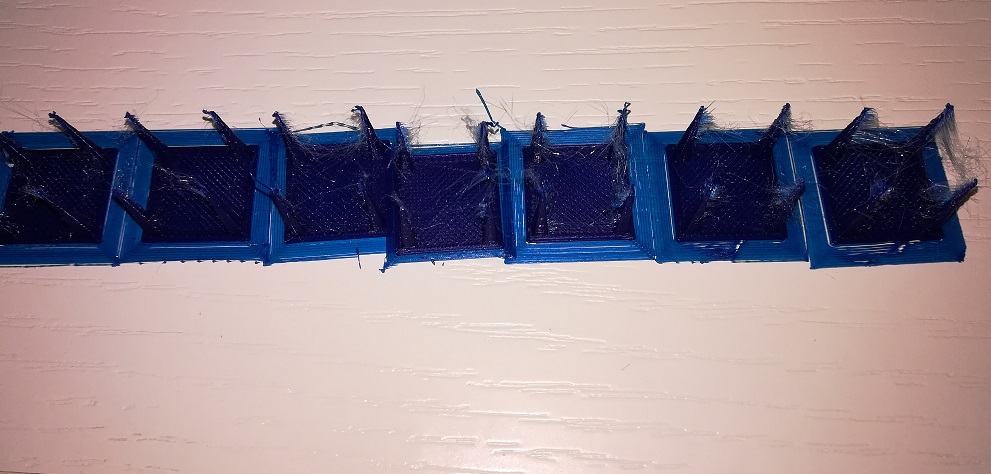

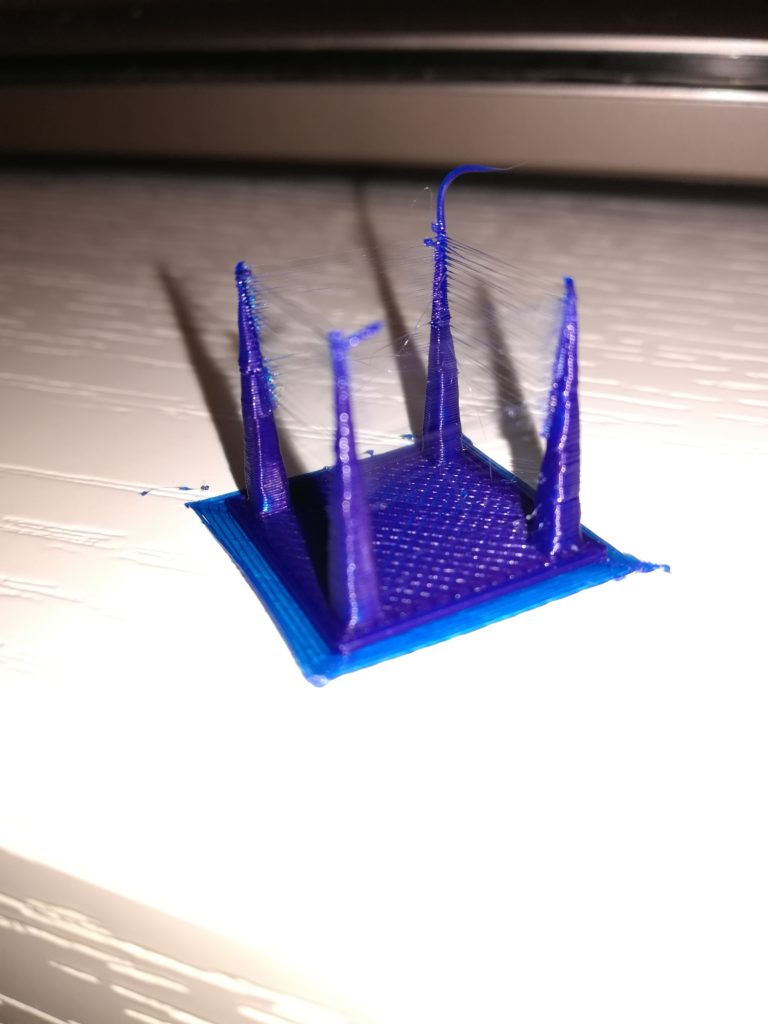

printing with these values I got this result

As you can see from the image, the cobweb or fluff is very abundant and the print finish is very bad. The effect of gravity casting on the tips of the four cones is evident. For the second test I purposely changed only the retraction distance to 6mm.

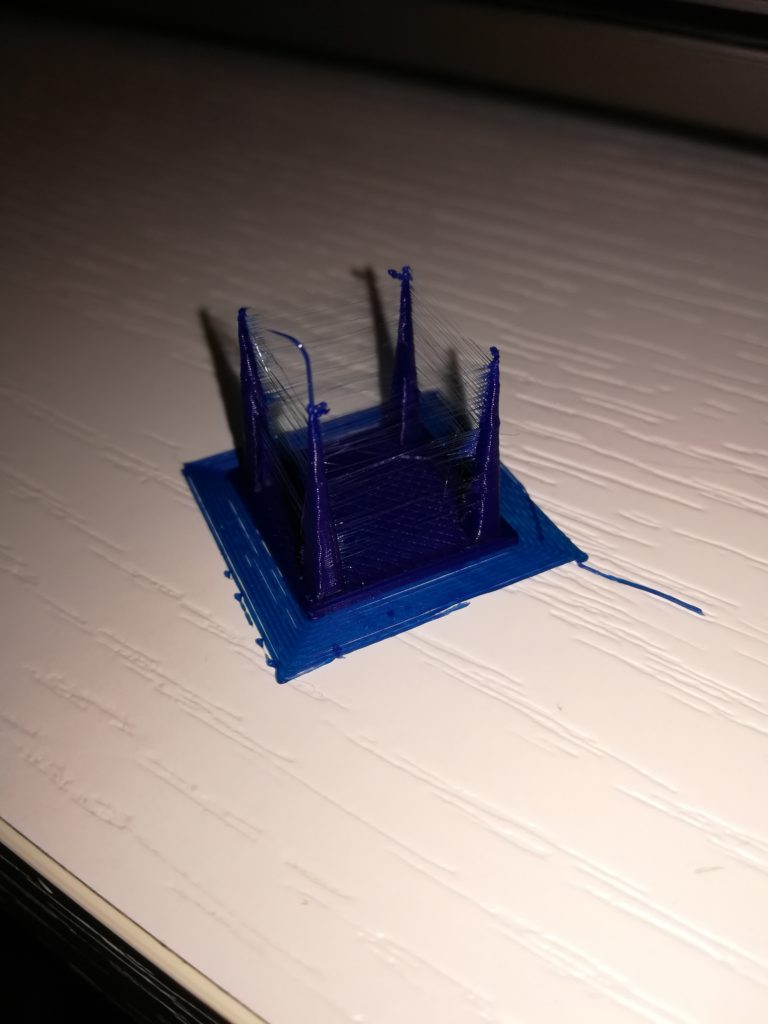

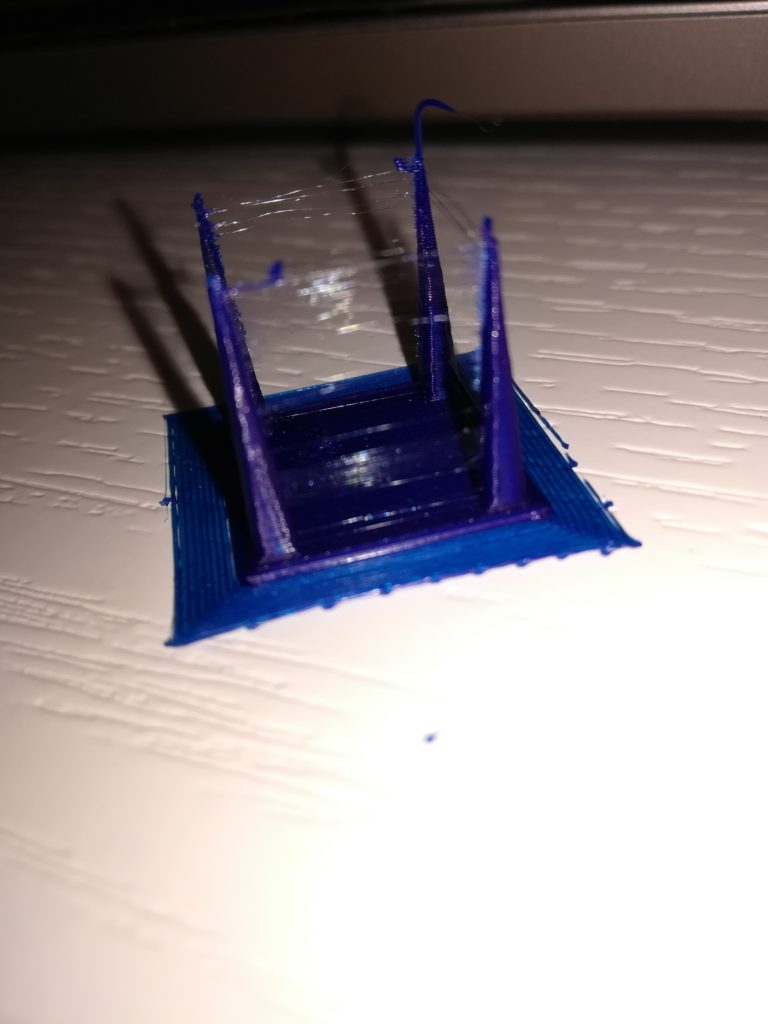

Maybe the image masks it a little but there was a very slight improvement. The web is less dense but imperfections on the tips of the cones remain evident. I therefore decided to lower the extrusion temperature from 210 ° to 208 ° and increase the retraction speed from 105 to 110mm / s.

here too the improvement was minimal, the tip of the cones always undergoes the casting effect, especially the last one in print order and the web, even if to a lesser extent, persists.

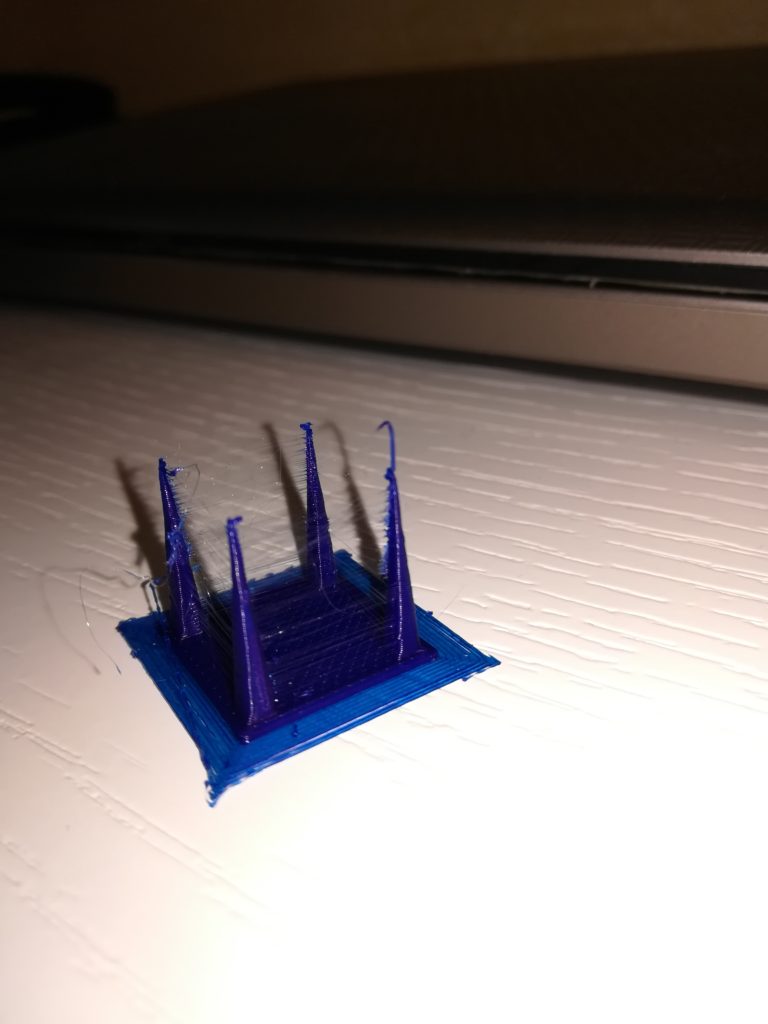

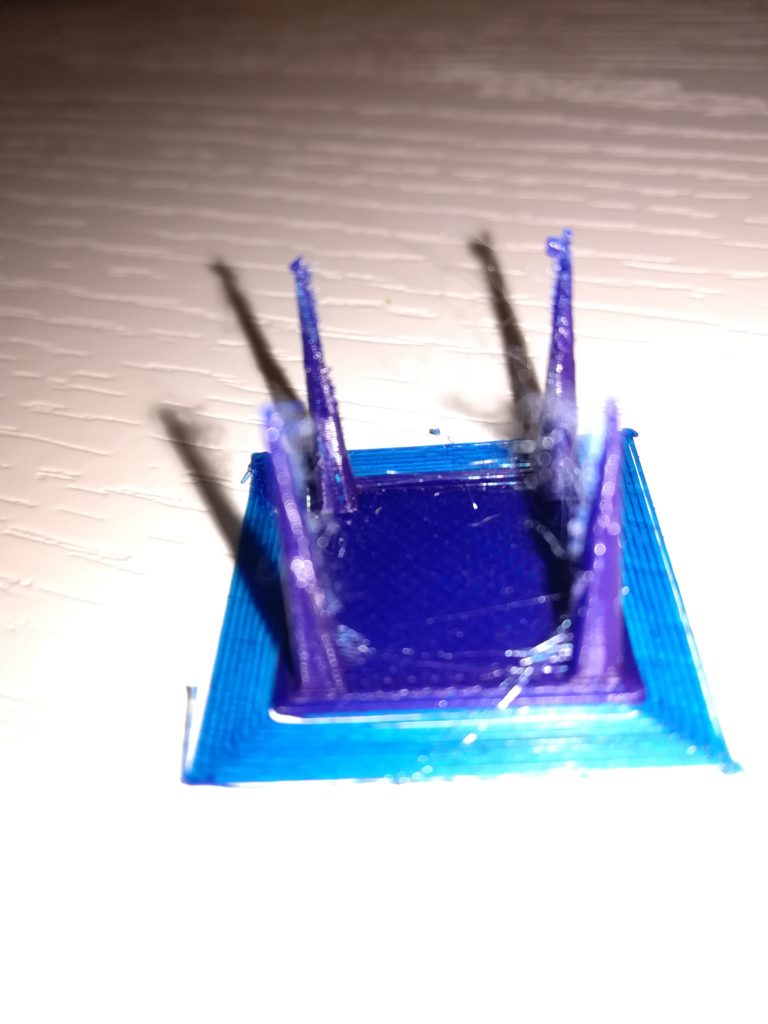

For the next print I decided to change other parameters that are not part of those of the retraction. I lowered the infill, i.e. the filling of the object, from 25% to 20%, brought the temperature back to 210 ° and I further lowered the flow rate from 90% to 85% due to the non-optimal conditions of the filament.

Here, even if the focus of the photo is on the bottom cones, the effect of the variations was felt more. The gravity casting on the last cone has disappeared, the web has drastically decreased and in general a cleaner print has come out, although certainly not good. I decided to carry out other tests leaving unchanged the last modified parameters, those not proper to the retraction and I drew some conclusions.

therefore?

It is possible to completely eliminate the cobwebs but it requires a very specific tuning for your printer, in particular the extruder and hotend, but in particular for the filament used. Even if produced by the same house, filaments of simply different colors have their best performance printed at different temperatures even if of a few degrees.

If the use of our printers is aimed at making objects of more or less regular shapes and not very small, finding satisfactory standard values will not be difficult, but if the prints we normally make are very close to the file used for the test, the my advice is not only to find optimal parameters, but also to always use the same filament, type, brand and color, otherwise to create your own profiles for each type we use.

It all depends on the result we want to achieve and how long we are willing to invest to do so.

A base on the parameters to play on now we have it and …. good prints at all … even if with a little hair ….

if you want to know more, if you need help write to info@3deasy.it

if you want to be updated on the next article, fill in the following fields to subscribe to the newsletter.