What is warping? warping is that defect that is sometimes created in our prints due to a characteristic of the materials we use for our 3d prints whether it is PLA, ABS, PTFE etc etc and which in practice consists in the enrichment of the ends of the bases of the our 3d prints.

Let’s see better ….

Like most existing materials, plastic, of any kind, undergoes changes in volume due to thermal variations. When we go to heat the filament in our hotend, in addition to changing from a solid state to a fluid one, it undergoes a volume variation that can affect the result even in a quite evident way. This not only happens when it heats up but also when it gets cold, naturally with the opposite consequence and with different characteristics depending on the material used.

Now let’s think about a piece with a fairly wide base and see what happens at the time of the first layer. The heated filament, for example at 210 °, is deposited on a much colder surface undergoing a thermal alteration which varies its dimensions by decreasing them. The second layer built on the first will have a warmer base than the first and therefore will undergo a different thermal shock and so on the third and fourth layer.

PLA, ABS, PTFE …. all the same?

Obviously not, for example, when cooled rapidly, PLA almost does not suffer this effect, on the contrary ABS which even gives its best when printed in a hot chamber. It comes by itself that each material has a different behavior. Of course, warping does not occur only for these reasons but also if we have an incorrectly leveled bed or our X and Y axes slide incorrectly. As we said above, the effect is mainly due to a thermal shock and in the case of materials that have a high operating temperature value, a heated plate certainly helps us to avoid the defect.

heated bed only?

All slicers offer help to reduce that our base detaches from the plate by curling at the ends. Let’s see what these settings are and how they work:

The least invasive of all is certainly BRIM. This setting does nothing but enlarge the dimensions of the support surface to the plate of the piece to be printed exclusively for the first layer. It is normally possible, in slicers, to also specify how much and obviously the wider it will be, the less chance the actual base of the piece will detach from the bed.

Keep in mind, however, that, as we said before, each material can undergo warping in a different way and in some cases another possibility offered by slicers can be useful and that is, useful for example for PLA, that of setting the use of fans to cool the piece only starting from a certain layer and also with what intensity.

Of course, the speed with which we print the first layer will also influence the creation of warping or not, the more we work slowly the better the adhesion to the bed.

Of course, a heated bed, for example at 50 ° / 60 ° for PLA or at 90 ° / 100 ° for ABS, helps to reduce the thermal shock that the first layer undergoes and therefore the possibility of warping.

Another remedy is to sprinkle the bed with a thin layer of hair spray that will act as a clinging agent. This, however, only in case of use of an unheated plate or in any case of a bed temperature lower than 60 ° because the hairsprays above this temperature crystallize, nullifying the “gluing effect” for which they are designed.

One more help from slicers ….

The thinner the thickness of the horizontal wall, the more likely it is that warping will occur. Simply by setting a higher value to our base wall, in slicer care at the BOTTOM item, the less chances of having warping will be.

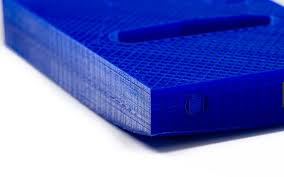

Drastic solution represents the use of RAFT. Try to think of the precarious boat with which a castaway on the usual desert island tries to reach the mainland present in all the themed films. A series of intertwined trunks that keep it raised from the waters of the seas infested by ferocious hungry sharks. Well the RAFT behaves exactly like a raft, keeping our piece raised from the bed to reduce the thermal shock from contact with the plate. Obviously with a little more precision than the raft I mentioned earlier.

Why drastic?

With RAFT we eliminate the possibility or almost that warping is created but as an undesirable effect we will have our base resting on the bed via a grating, a grating that we will then have to remove and which will inevitably leave marks on our piece.

So far we have seen economic solutions to counter warping but if you want to invest something you can buy plates specially designed and designed to improve adhesion or specific products for 3d printing such as kapton.

if you want to know more, if you need help write to info@3deasy.it

if you want to be updated on the next article, fill in the following fields to subscribe to the newsletter.