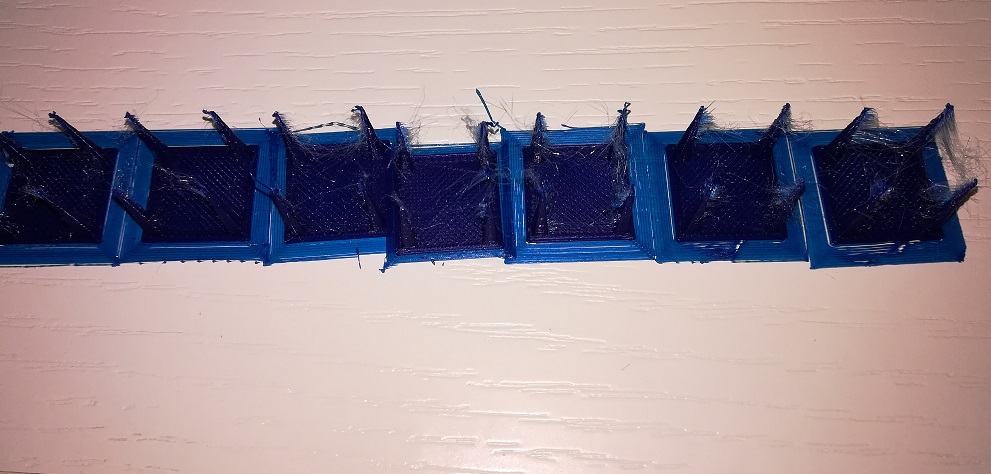

not manifold, we understand what it means and how to remedy it

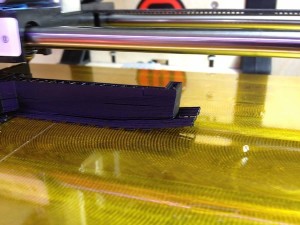

When we design and then draw a three-dimensional model to then be able to make it printed in 3d, we must take into account many factors, for example that the slicer will have to “slice” it to obtain all the coordinates to be used to carry out the physical construction by layering our three-dimensional object.

Once the drawing is finished and our file is fed to the slicer, we can find ourselves in front of a warning message that tells us “attention, the object is not manifold”.

What does it mean? In the case of 3d printing, a non-manifold object is an “non-closed” object, that is, it has imperfections that do not allow continuity during the printing phase. For example, it may be a wall that we apparently designed perpendicular to another but which actually has a minimal, practically invisible, deviation from the contact one.

Continue reading NOT MANIFOLD…HOW TO TAKE REMEDY IN A SIMPLE WAY